Bridgville Plastics can handle a range of tooling and engineering services for manufacturing processes. With the right equipment and expertise, Bridgville Plastics can affordably build/manufacture almost any part or product.

So what are some benefits of tooling and engineering services? There are many benefits.

Quick Turnarounds

Consider tooling services. The tooling process involves making a part, mold or prototype for you. Do you want to get your tooling work done quickly? If so, that means you can finalize your design and get whatever it is you want made into the hands of customers sooner than later. Computerized models can be made fairly quickly. Automated machinery can test your design and move it to the manufacturing stage in a timely manner.

Testing out Ideas

Do you need to test out new ideas? Do you want to make design adjustments? Use rapid tooling to make multiple prototypes or molds in a quick way such that you can choose your favorite/best one. Oftentimes, people will choose injection-molded parts in order to then create as many parts from the mold as needed. In fact, a mold can be used to test out different materials to see which performs best for the item you want to create. Use the mold to make multiple prototypes which can then go through quality control tests to determine the best choice for the final product.

Less Development Means Stronger ROI

If you’re like most companies, you want a return on your investment, and you want it quickly. You don’t have time to wait around for profits, right? That means you want to lessen product development time so you can quickly get your product to market and recoup upfront expenses incurred. Tooling can make that happen! This is especially helpful for businesses with limited production budgets.

A Variety of Options

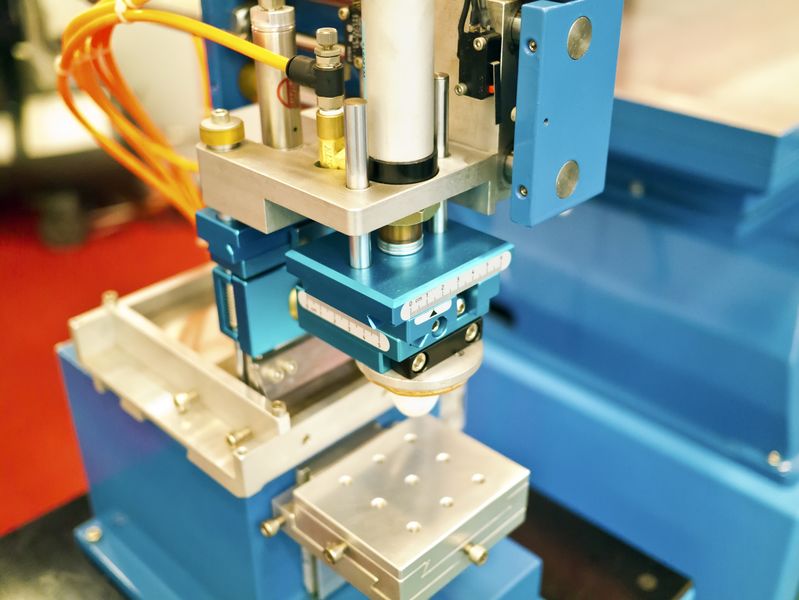

Tooling can be done in a number of ways these days, including through the use of 3D printers, CNC machines, metal sintering tools, and robotic/automated systems. If you choose to work with a skilled contract manufacturer, you’re going to have access to efficient and advanced tools to get your goals accomplished.

Engineering Services

Like tooling services, engineering services have many benefits. As you try and develop your product, for example, it helps to have engineering support. You gain the knowledge of someone else’s experience in order to make your experience smoother. Engineers have a wealth of experience; They’re generally well-educated, too. Add to that certifications, and you have smart people to work with on your project(s). Keep in mind that engineers have experience working on designs, making needed adjustments, and figuring out what works and what doesn’t work. They know about different materials and processes. Some of the specific benefits of engineering support include cost savings, risk mitigation, and a strong focus on reaching intended goals.

Do you know that about 80 percent of the cost of a product is determined during its design phase? Therefore, it makes sense to have engineers involved in the design phase of your product, part or mold. It’s cheaper to change a design early in the development process than it is to change it later on down the line. Furthermore, engineers bring with them a wealth of knowledge from different experiences and industries, which can help reduce operational risk by applying tested solutions.

Less Time to Market

Time to market matters, doesn’t it? We live in a time-sensitive culture where everyone wants everything immediately. Engineers can help with project management, specifically managing the activity of technical product development. Multi-tasking is usually involved, and engineers figure out which tasks can be done at what times in order to fast-track the whole process without significantly increasing risk.

Cost Effective

Are you looking for a high-value, cost-effective design? Engineers follow guiding principles that ensure high quality products are made for the lowest cost(s) possible. Furthermore, they challenge a design, finding ways to make it better without sacrificing its quality or performance. Engineers know how to combine (or eliminate) parts that can help save money when it comes to costs, labor, overhead, etc. Other things engineers can “bring to the table” include the use of computer analysis to evaluate components/design, as well as making parts design-friendly for either human hands to create or automated machines (or a combo of both). If material alternatives are needed, engineers know what else to choose… and if new technologies are emerging, engineers should be able to consider them for your project, too.

There are many benefits to engineering and tooling services. If you need either or both, call Bridgville Plastics at 269-465-6516 today or use the contact page here.